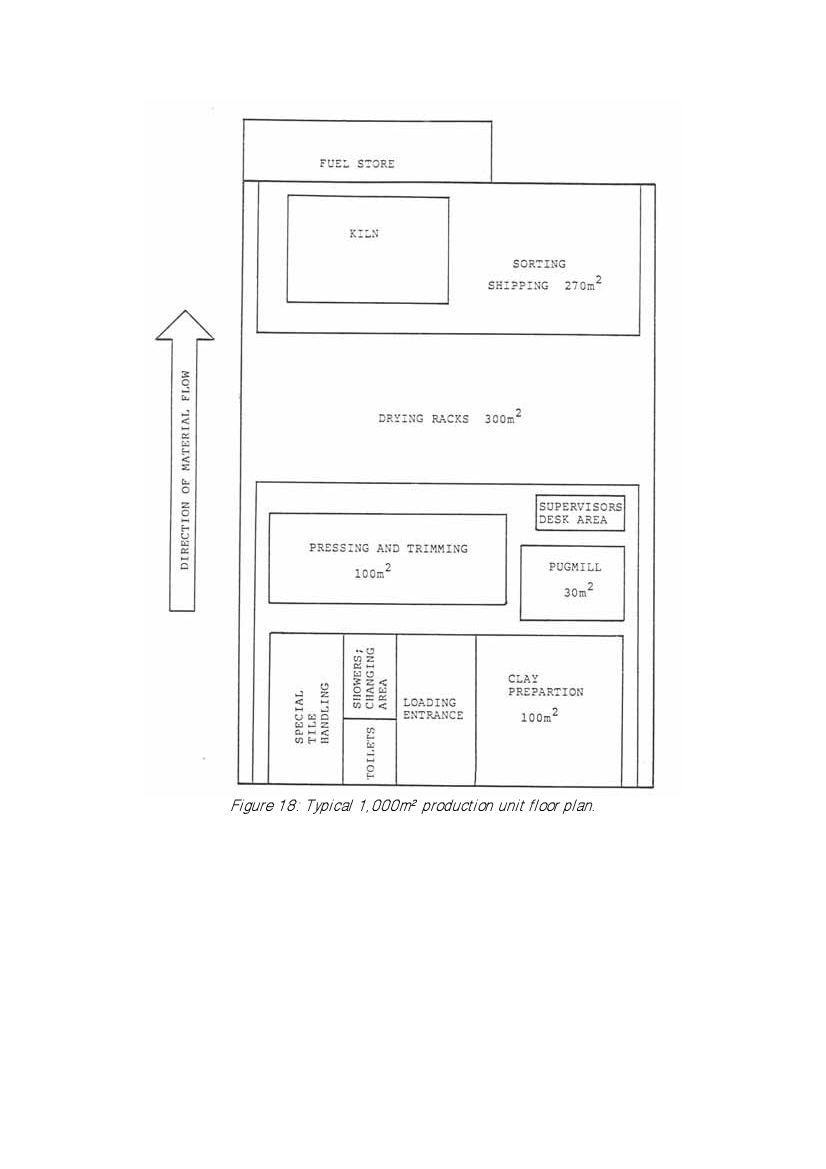

Figure 18: Typical 1,000m2 production unit floor plan.

The drying racks account for a great deal of factory area, and therefore must be planned

carefully. When climate is very dry, tiles may be fired after only five days, whereas in wet,

cool, or humid conditions drying will take up to 10 days. Thus the total rack area needs to be

adjusted according to prevalent climatic conditions. Clay type, water content, air circulation

and tile design also influence the drying time. The only reliable method of determining your

requirements is to run tests. In an area where there is no data on tile drying it is best to plan

on a one week drying period as a starting figure, or slightly higher if the area is wet or cool.

For the production unit described in this text, a building of approximately 1,000m2 is

adequate for single shift six day per week production. Drying racks are put along all available

exterior walls to take advantage of the increased air circulation for drying.